Excellence and Professionalism

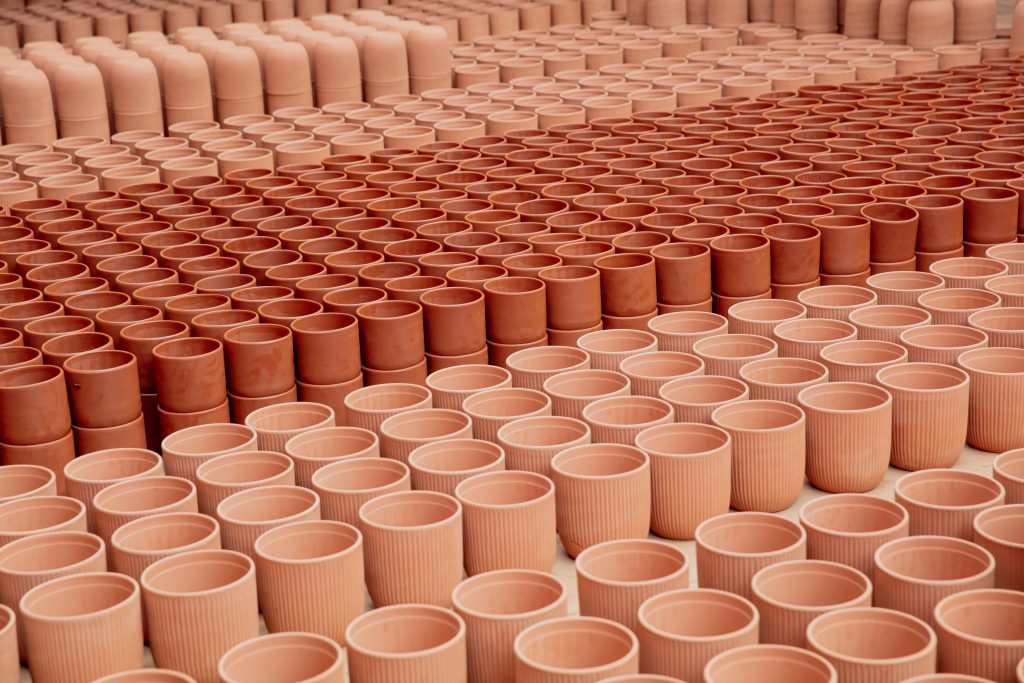

- At Long Truong Ceramics, we pride ourselves in providing our customers a wide selection of high quality and well-designed products.

- Our product development team is always exploring and creating new colors, shapes, finishes, and textures to ensure that we offer unlimited possibilities. Customers are also more than welcome to work with us to create a design that best suits their needs. We will produce and deliver the samples to you within 14 days.

- Long Truong Ceramics has continuously expanded since day one, currently operating with:

Manufacturing Facility

170000m2

Products

3000000pieces/month

Container Capacity

250conts/month

Experience in Powder Coating

20years

Mission & Vision

- Become essential to our customers by providing a wide range of high quality products created with a balance between design, quality, and price in mind.

- Our vision is to bring sustainable quality and innovation to every customer we serve.

Core Values

- Sustainability here means far beyond good quality. We do everything with a long-term perspective which naturally reflects in stable price, stable quality, and our continuous efforts to better ourselves for the better of our customers.

- People – at Long Truong Ceramics, we value conscientiousness, collaboration, and creativity. A proactive, dedicated work attitude, a sense of responsibility and teamwork, and creative thinking skills are at the core of our company culture.

Our Factory

Our Commitment

We Listen

Customers are always at the center of our business and this permeates every decision we made. We listen and appreciate all feedback and suggestions because we believe that every single customer is an active and central participant in our value creation process.

We Understand

We put ourselves in the shoes of our customers to find the right solution for their issues and the innovative approach for their satisfaction.

We Create

This customer-centric culture comes from the top down, through the frontline teams and delivers straight to customers. We look after our employees by recognizing hard work, listening to their needs and creating a healthy and proactive work environment so that they can then look after our customers. We strive to provide the right tools and training to empower them to deliver wholeheartedly and consistently. This is how we create value for our customers.

Development History

Customer Service